How do you sublimate aluminum bottles?

Sublimation is a popular technique used in printing designs on various surfaces, including aluminum bottles. Aluminum bottles have become increasingly popular due to their durability, lightweight, and eco-friendliness. Sublimating aluminum bottles requires some specialized equipment and techniques that can heat the ink to its vaporization point without burning it. In this article, we will discuss how to sublimate aluminum bottles and the equipment and techniques required.

Equipment Required for Sublimating Aluminum Bottles

Sublimation printing on aluminum bottles requires some specialized equipment, including:

Sublimation printer: A sublimation printer uses sublimation ink to print the desired design onto sublimation paper.

Sublimation ink: Sublimation ink is specially formulated to turn into a gas at high temperatures without leaving any residue behind.

Sublimation paper: Sublimation paper is used to print the design onto the paper using the sublimation printer. The design is then transferred onto the aluminum bottle using heat and pressure.

Heat press machine: A heat press is used to apply heat and pressure to the sublimation paper, causing the ink to turn into a gas and permeate the aluminum bottle.

Heat press for sublimating aluminum bottles recommended:

Double Station Mug Heat Press Machine, Suitable for high-efficiency sublimation printing;

Handheld Heat Press, Economical and suitable for home DIY;

20 OZ Tumbler Heat Press, Affordable for personal and business use;

30 OZ Mug Press Machine, Suitable for sublimation more size mugs.

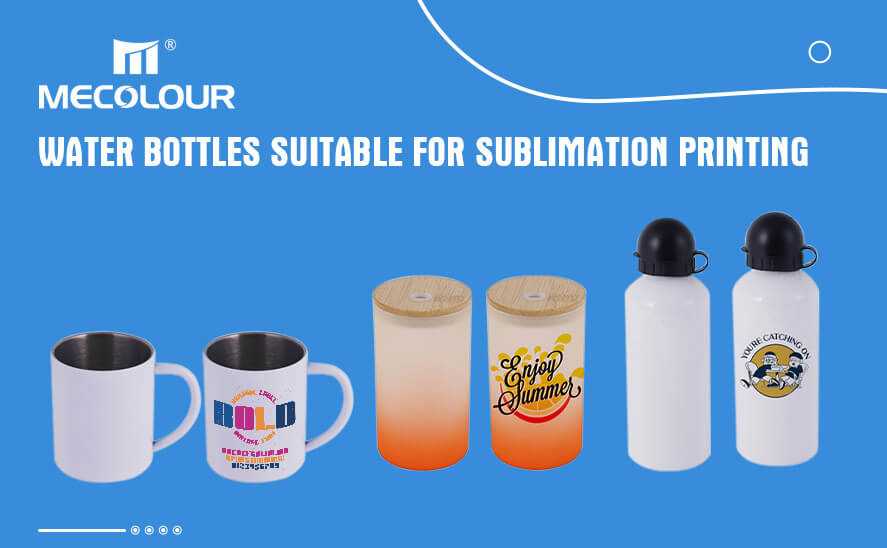

Aluminum bottles: Aluminum bottles are the substrate onto which the design is transferred. It is important to use high-quality aluminum bottles that are designed for sublimation printing.

Steps for Sublimating Aluminum Bottles

Sublimating aluminum bottles requires several steps, including:

Choose the design: Choose the design you want to print on the aluminum bottle. Ensure that the design is high-quality and suitable for sublimation printing.

Print the design: Use a sublimation printer to print the design onto sublimation paper. The design should be printed in mirror image so that it will appear correctly on the aluminum bottle.

Prepare the aluminum bottle: Clean the aluminum bottle thoroughly to remove any dust or debris that may interfere with the sublimation process.

Apply the transfer: Place the sublimation paper onto the aluminum bottle and secure it with heat-resistant tape. Ensure that the transfer is positioned correctly and securely.

Heat and press: Place the aluminum bottle and sublimation paper onto the heat press and apply heat and pressure according to the manufacturer’s instructions. The temperature and pressure may vary depending on the type of heat press and the size of the aluminum bottle.

Remove the transfer: Once the sublimation process is complete, remove the sublimation paper from the aluminum bottle. The design should now be transferred onto the aluminum bottle, creating a permanent, high-quality image.

Inspect and package: Inspect the aluminum bottle to ensure that the design has transferred correctly and that there are no defects. Once the aluminum bottle passes inspection, it can be packaged and shipped.

How to diy a sublimation sports water bottle? Please watch this video to learn more.

Tips for Sublimating Aluminum Bottles

Here are some tips for sublimating aluminum bottles:

Use high-quality aluminum bottles designed for sublimation printing. Low-quality aluminum bottles may not withstand the high heat and pressure required for sublimation printing.

Ensure that the design is high-quality and suitable for sublimation printing. Low-resolution designs may result in blurry or pixelated images.

Clean the aluminum bottle thoroughly before applying the transfer to ensure that the design adheres correctly.

Use a heat press with accurate temperature and pressure control to ensure that the sublimation process is successful. If the heat and pressure are not applied correctly, the design may not transfer correctly, resulting in a low-quality image.

Experiment with different heat and pressure settings to find the optimal settings for your particular aluminum bottle and design.

Consider using a heat-resistant adhesive spray to secure the sublimation paper to the aluminum bottle before applying it to the heat press. This can help prevent the sublimation paper from shifting during the sublimation process.

Avoid touching the aluminum bottle immediately after the sublimation process, as it will be very hot. Allow the bottle to cool before handling it.

In conclusion, sublimating aluminum bottles can produce high-quality, long-lasting images that are perfect for personalized products. The process requires specialized equipment and techniques, but with the right equipment and some practice, it is relatively straightforward. Remember to use high-quality materials, experiment with different heat and pressure settings, and follow the manufacturer’s instructions carefully to achieve the best results. With these tips in mind, you can create beautiful, personalized aluminum bottles that will be cherished for years to come.

Mecolour Factory is a supplier specializing in the production and sales of sublimation consumables and equipment for your DIY life. Bulk purchase of sublimation blank mugs, equipment and accessories, please feel free to contact us!