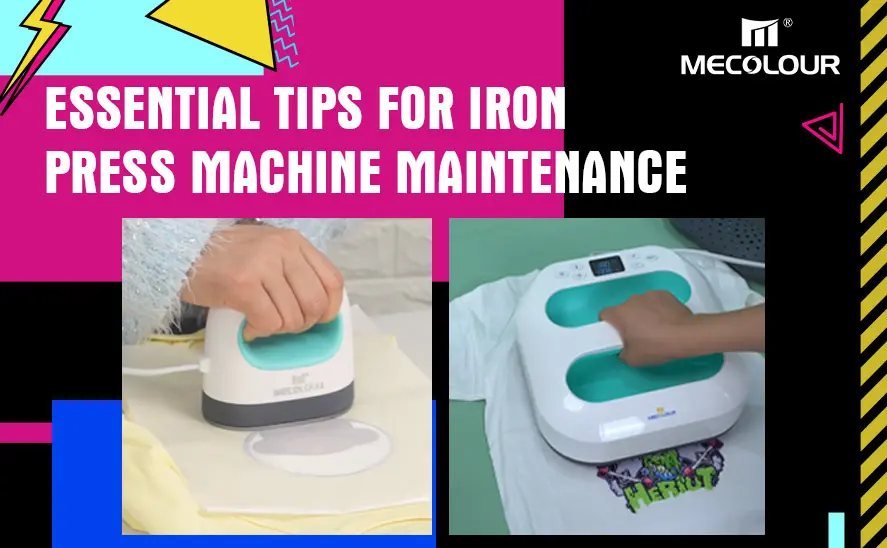

Essential Tips for Iron Press Machine Maintenance

Iron press machines are vital tools in both home and commercial settings, offering efficiency and precision in garment pressing tasks. Proper maintenance is essential to ensure these machines function optimally and have a long lifespan. This comprehensive guide provides essential tips for maintaining your iron press machine, helping you achieve the best results and avoid unnecessary repairs.

1. Regular Cleaning

Clean the Press Plate

The press plate is the most crucial component of your iron press machine. Residue from transfers, adhesives, and fabrics can accumulate on the plate, affecting its performance and potentially damaging garments.

- Daily Cleaning: After each use, wipe the press plate with a clean, dry cloth to remove any loose debris.

- Weekly Cleaning: Use a mild cleaner or a specialized heat press cleaner to remove any stubborn residue. Ensure the plate is cool before cleaning.

- Avoid Abrasives: Do not use abrasive materials or harsh chemicals, as they can scratch or damage the plate.

Clean the Machine’s Exterior

Dust and dirt can accumulate on the machine’s exterior, particularly around the control panel and hinges.

- Wipe Down: Regularly wipe the exterior with a damp cloth to keep it clean and free of dust.

- Protect the Controls: Ensure the control panel is dry and free of dust to prevent malfunctions.

2. Check and Adjust Pressure Settings

Maintain Consistent Pressure

Consistent pressure is essential for achieving even heat transfers and pressing results.

- Test Regularly: Periodically test the pressure settings to ensure they are accurate and consistent.

- Adjust as Needed: Adjust the pressure settings based on the thickness and type of fabric you are pressing. Refer to the manufacturer’s guidelines for specific recommendations.

3. Inspect and Maintain Electrical Components

Check Cords and Connections

Electrical components are crucial for the safe and efficient operation of your iron press machine.

- Inspect Regularly: Regularly inspect power cords, plugs, and connections for signs of wear or damage.

- Replace Damaged Parts: Immediately replace any damaged or frayed cords to prevent electrical hazards.

Monitor Heating Elements

The heating element is responsible for providing even heat distribution across the press plate.

- Check for Even Heat: Periodically test the heating element to ensure it is providing consistent and even heat across the entire plate.

- Replace if Necessary: If you notice uneven heating or hot spots, consult the manufacturer’s guidelines for replacing the heating element.

4. Lubricate Moving Parts

Maintain Smooth Operation

Lubrication is essential for the smooth operation of moving parts, such as hinges and levers.

- Use Appropriate Lubricants: Use a lubricant recommended by the manufacturer to prevent friction and wear.

- Apply Sparingly: Apply the lubricant sparingly to avoid buildup and ensure smooth operation.

5. Store Properly When Not in Use

Protect from Dust and Moisture

Proper storage is crucial to maintain the longevity and functionality of your iron press machine.

- Cover the Machine: Use a dust cover or cloth to protect the machine from dust and debris when not in use.

- Store in a Dry Place: Ensure the machine is stored in a dry, cool place to prevent moisture damage.

Lock and Secure

Many iron press machines come with locking mechanisms to secure the press in a closed position.

- Engage Locking Mechanism: When storing the machine, engage the locking mechanism to protect the press plate and maintain pressure settings.

6. Follow Manufacturer’s Maintenance Guidelines

Refer to the Manual

Each iron press machine comes with specific maintenance guidelines provided by the manufacturer.

- Read the Manual: Thoroughly read and follow the manufacturer’s maintenance instructions.

- Schedule Regular Maintenance: Adhere to the recommended maintenance schedule to keep your machine in optimal condition.

Proper maintenance of your iron press machine is essential to ensure it operates efficiently and has a long lifespan. By following these essential maintenance tips, you can achieve consistent, high-quality results and avoid costly repairs. Regular cleaning, pressure adjustments, electrical inspections, lubrication, proper storage, and adherence to manufacturer’s guidelines will keep your machine in top condition.