What common problems occur when using a heat press?

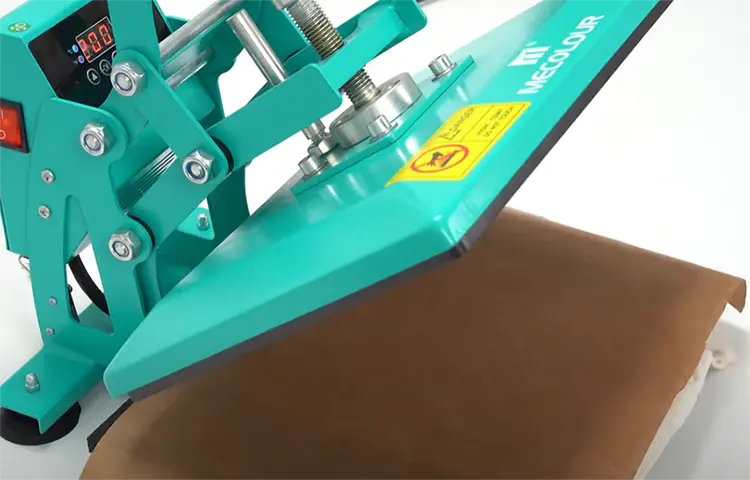

A heat press is an invaluable tool for transferring designs onto garments, mugs, and other materials. However, even seasoned users can encounter issues during the process. Let’s explore the most common problems that occur when using a heat press and how to resolve them.

Common Problems When Using a Heat Press

1. Uneven Heat Distribution

The Problem

Some areas of the design don’t transfer properly, leaving incomplete or faded sections.

The Cause

Uneven pressure distribution across the heat press platen.

Faulty heating element or hot spots on the press.

The Fix

Use a heat press temperature test strip or an infrared thermometer to check for consistent heat.

Ensure the pressure is evenly distributed by adjusting the platen screws or using a pressing pillow for uneven surfaces.

2. Peeling or Cracking Designs

The Problem

The design starts peeling off or cracking after the transfer process.

The Cause

Incorrect temperature, pressure, or time settings.

Poor-quality transfer paper or vinyl.

The Fix

Double-check the manufacturer’s recommendations for temperature, time, and pressure based on the material and transfer type.

Invest in high-quality heat transfer vinyl or sublimation paper.

3. Scorched Material

The Problem

The fabric or material turns brown, black, or develops burn marks.

The Cause

Excessive heat or time during the pressing process.

The Fix

Lower the temperature setting and reduce pressing time for sensitive fabrics.

Use a protective Teflon sheet or parchment paper between the heat platen and the material.

Use a protective Teflon

4. Ghosting or Double Images

The Problem

The transferred design appears blurry or duplicated.

The Cause

The transfer paper shifted during the pressing process or while lifting the heat platen.

Incorrect pressure settings.

The Fix

Secure the transfer paper with heat-resistant tape to prevent movement.

Avoid sudden movements when closing or opening the press.

5. Adhesion Issues

The Problem

The design doesn’t stick properly to the material, even after pressing.

The Cause

Incompatible material for the chosen transfer type.

Using a garment with residue, moisture, or dirt.

The Fix

Confirm that the material is compatible with the transfer method (e.g., cotton for HTV, polyester for sublimation).

Pre-press the garment for 3–5 seconds to remove moisture and wrinkles before applying the design.

6. Color Fading or Inaccuracy

The Problem

Colors appear dull, washed out, or inaccurate after pressing.

The Cause

Incorrect ink or sublimation paper for the transfer process.

Insufficient temperature or pressing time.

The Fix

Use sublimation ink for sublimation transfers and ensure the paper matches your printer type.

Follow recommended heat and time settings carefully.

7. Uneven Pressure Marks

The Problem

Visible outlines or pressure marks appear around the design.

The Cause

Excessive pressure or a poorly aligned platen.

The Fix

Adjust the pressure settings to ensure it’s firm but not overly tight.

Use a silicone pressing pad or Teflon sheet to soften the impact.

8. Difficulty Removing Transfer Paper

The Problem

The transfer paper sticks to the material and tears when peeled off.

The Cause

Incorrect peel temperature (hot peel vs. cold peel).

The Fix

Check the transfer paper instructions to see whether it requires a hot peel (immediate removal) or cold peel (waiting until it cools).

9. Overlapping or Misaligned Designs

The Problem

The final design is crooked, misaligned, or parts overlap improperly.

The Cause

Poor placement or lack of alignment tools during setup.

The Fix

Use a heat press alignment tool or ruler to position your design before pressing.

Apply transfer tape or guides for multi-layer designs to ensure proper alignment.

10. Inconsistent Results Across Batches

The Problem

One batch of designs turns out perfect, but the next is full of errors.

The Cause

Variations in settings, materials, or environmental factors like humidity.

The Fix

Standardize your process by keeping notes on successful settings for each material.

Ensure your workspace is temperature-controlled and free of excess moisture.

Using a heat press effectively requires attention to detail and proper technique. Most issues stem from incorrect settings, poor-quality materials, or lack of preparation. By understanding common problems and their solutions, you can achieve professional results consistently.

Related:

Mastering Heat Press Techniques for Sublimation Tumblers

Essential Tumbler Heat Press Care Tips