Mug Press Maintenance – Our Top Tips

Owning a mug press means you’re investing in a vital piece of equipment for your business or hobby, whether it’s for creating custom mugs or expanding your product range. Mug press maintenance is essential to ensure its longevity, performance, and reliability. This comprehensive guide will help you maintain your mug press machine, offering tips, techniques, and troubleshooting advice that guarantees your equipment stays in top-notch condition for years to come.

How to effectively maintain mug press?

1. Regular Cleaning and Inspection

One of the simplest yet most effective maintenance tasks for any mug press machine is regular cleaning. Dirt, ink, and residue from your projects can accumulate on the press, affecting its performance and lifespan.

How to Clean Your Mug Press

- Turn off the power and unplug the machine before cleaning to avoid accidents.

- Use a soft cloth to wipe down the exterior, ensuring there’s no ink or dust build-up.

- For stubborn ink stains, apply a mild soap solution or special cleaning solution specifically designed for heat press machines.

- Pay special attention to the heating elements. Gently remove any residue with a non-abrasive brush or cloth.

- Check the pressing plates and ensure they’re free from scorch marks or burnt residue, which can damage the material.

Inspection Tips

While cleaning, always perform a visual inspection. Look for any signs of wear and tear such as:

- Loose screws or bolts

- Cracks in the housing or press plates

- Signs of electrical issues, like frayed cords or exposed wires

Taking care of these minor issues early on can prevent costly repairs or downtime later.

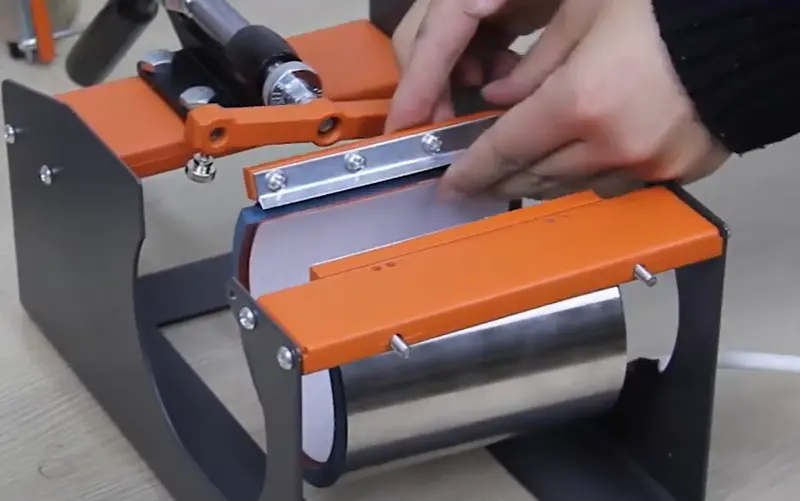

2. Lubrication of Moving Parts

Just like any other machine with moving components, lubrication is vital to ensure smooth operation and reduce wear. The mug press machine relies on several moving parts that can become worn out if not properly maintained.

Where to Lubricate

- The adjustable pressure knobs and hinges should be lubricated regularly to ensure smooth and efficient operation.

- Apply machine oil or silicone-based lubricant to moving parts.

- Do not use heavy grease as it can attract dust and dirt, affecting the machine’s performance.

A good rule of thumb is to lubricate your machine every 20 to 30 hours of use or whenever you notice any stiffness in the movement of the parts.

3. Calibrate the Temperature and Pressure Settings

The temperature and pressure settings of your mug press are essential for achieving high-quality results. Over time, these settings may drift, affecting the consistency of your prints.

How to Calibrate Your Mug Press

- Use a digital thermometer to check the internal temperature of the mug press. Compare the actual temperature with the set value to ensure they match.

- Adjust the pressure settings by following the manufacturer’s instructions to guarantee that the pressure is consistent across different projects.

- Some models come with a built-in pressure gauge, but if yours doesn’t, ensure that you have a reliable one on hand to regularly check the pressure.

Regular calibration ensures that each print is crisp, vibrant, and consistent, preventing issues like faded designs or uneven applications.

4. Check Electrical Components

Electrical failures are one of the most common issues with mug presses. Faulty wiring or burned-out components can cause significant malfunctions, so inspecting the electrical components is vital.

Electrical Maintenance Tips

- Regularly inspect power cords and plugs for signs of damage, such as fraying, exposed wires, or burns.

- If your mug press machine has a digital display, ensure the screen is working properly and showing the correct information.

- Check the circuit board for any signs of overheating or damage.

- If your mug press operates at higher voltage levels, ensure that the wiring and connections are secure and safe to prevent electrical surges.

When performing electrical maintenance, always follow safety protocols. If you’re unsure about the condition of any components, it’s best to consult a professional technician to avoid electrical hazards.

5. Store Your Mug Press Properly

Where and how you store your mug press can have a huge impact on its overall lifespan. Exposure to extreme temperatures, moisture, or dust can all cause damage to the machine.

Proper Storage Guidelines

- Store the machine in a dry, cool environment, away from humidity or direct sunlight.

- If you’re storing the mug press for an extended period, ensure it’s covered with a protective dust cover to prevent dust and debris from accumulating on the machine.

- Avoid storing the press in areas with high moisture levels like basements or garages, as this can lead to rust or electrical problems.

Proper storage ensures that your mug press stays in top condition and is ready for use whenever you need it.

6. Replace Worn-out Parts Promptly

Even with regular maintenance, some parts of your mug press will inevitably wear out over time. These components should be replaced as soon as possible to avoid more significant problems or a complete breakdown.

Replace Worn-out Parts Promptly

Common Parts That Need Replacement

- Heat pads: These can wear out after extended use and may show signs of wear, cracking, or uneven heating.

- Pressure pads: If the pressure pads start to lose their cushion or shape, they can cause uneven prints, and it’s time to replace them.

- Wires and plugs: Over time, these can become frayed or damaged, leading to electrical issues.

When replacing parts, always use genuine manufacturer parts to ensure compatibility and optimal performance.

7. Troubleshooting Common Issues

Despite regular maintenance, your mug press may encounter some common issues. Below are a few troubleshooting tips to help you resolve them quickly.

(1) The Mug Press Isn’t Heating Up

Check the power source to ensure it’s properly connected.

Inspect the heating element for any signs of damage or malfunction.

Test the thermostat or temperature probe to ensure they are working correctly.

(2) The Design Isn’t Transferring Well

Adjust the pressure to ensure even contact between the mug and the heat press.

Increase the temperature slightly if the design is not transferring properly.

Ensure that the transfer paper and ink are compatible with the type of mugs you’re using.

(3) The Machine Is Making Unusual Noises

This could indicate that parts need lubrication or are becoming loose. Inspect the moving parts and tighten any bolts or screws that may have come loose.

8. Preventative Maintenance for Longevity

Preventative maintenance is always more cost-effective than repair or replacement. By regularly cleaning, lubricating, and inspecting your mug press, you can prolong its life and prevent unexpected failures.

Maintenance Schedule

Daily: Wipe down the exterior, check for any loose parts or visible damage.

Weekly: Lubricate the moving parts, calibrate the temperature and pressure settings.

Monthly: Inspect electrical components, replace worn-out parts as needed.

Annually: Perform a deep clean, replace any parts that have reached the end of their lifespan.

Following a consistent maintenance schedule will ensure your mug press performs at its best for years to come.

Related:

Mug Press Machine: Personalized Printing Solutions

Selecting the Right Mug Press for Your Needs

Top Mistakes to Avoid in Sublimation Mug Printing

10 common problems and 17 advanced tips in mug sublimation printing