What Do You Need for UV DTF Printing?

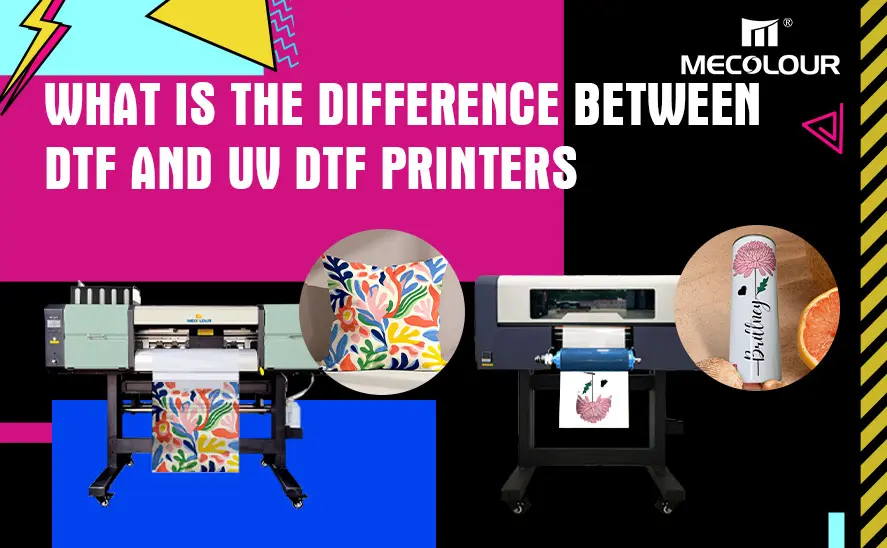

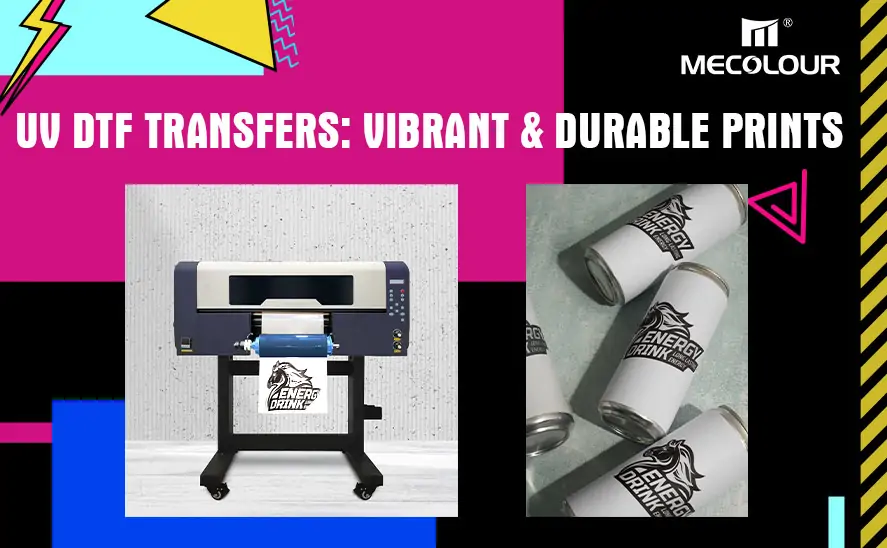

UV Direct-to-Film (DTF) printing is a modern, high-quality printing method used to transfer vibrant designs onto various surfaces. To create UV DTF transfers, you need several key components that work together to produce high-quality, durable prints. These essential items include specialized printers, inks, films, and equipment. Here’s a detailed breakdown of what you need for UV DTF printing:

1. UV DTF Printer

The UV DTF Printer is the core of the UV DTF printing process. This specialized printer uses UV DTF inks to print designs onto transfer film. The printer must be capable of high-resolution printing and designed to work with UV-curable inks. When selecting a UV DTF printer, consider:

- Print Head Technology: A high-quality print head ensures sharp details and color accuracy in your prints.

- Ink Compatibility: The printer should be designed to handle UV DTF inks for optimal performance.

- Media Size: Ensure the printer can accommodate your required transfer film sizes.

2. UV DTF Inks

UV DTF Inks are essential for achieving vibrant, durable prints. These inks are specially formulated to be cured using UV light. They bond strongly with various materials, making them ideal for transferring designs onto ceramics, metals, plastics, and more hard surfaces. Key points about UV DTF inks include:

- Fast Curing: UV inks cure almost instantly under UV light, ensuring high productivity.

- Color Vibrancy: UV inks produce vivid, long-lasting colors that don’t fade quickly.

- Durability: The cured inks are highly resistant to abrasion, UV exposure, and washing.

3. UV DTF Film

UV DTF Film is a special transfer film that receives the printed design before the process transfers it to the substrate. It must be compatible with UV DTF inks for proper adhesion. Some features of UV DTF film include:

- Smooth Surface: The film has a smooth, non-porous surface to ensure the ink adheres well without bleeding.

- Durability: The film should be strong enough to handle the heat transfer process without tearing or distorting the print.

- Transparency or White Base: Depending on the design, some films are transparent, while others have a white backing to help the print colors pop.

How To Use UV DTF FILM DIY Glass Tumbler

4. Substrate

The final material, or substrate, onto which the design will be transferred, can vary. Common substrates include:

- Plastics: Like polypropylene (PP) and polystyrene (PS), used for packaging and labels.

- Metals: Such as aluminum and stainless steel, suitable for beverage bottles and electronic device casings.

- Wood: Used for furniture and decorative items.

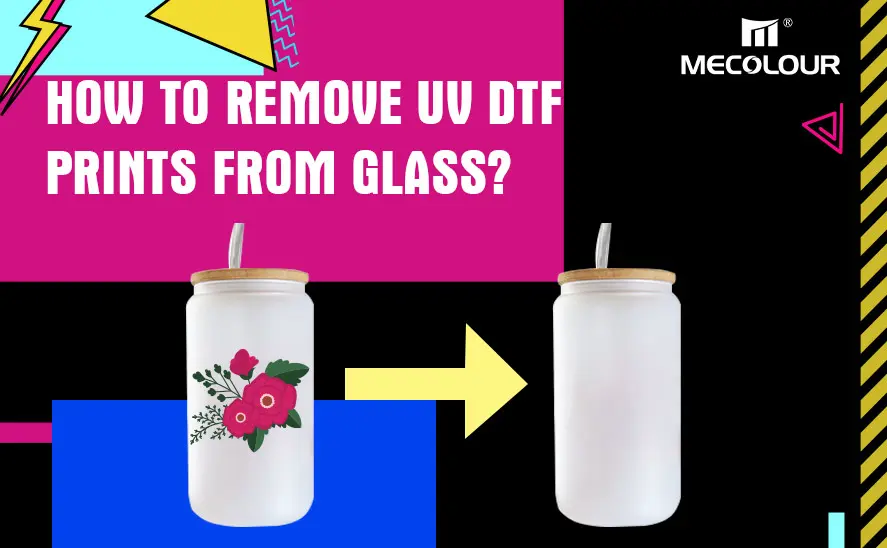

- Glass: Suitable for bottles and window decorations.

- Leather: For making shoes, bags, and other leather goods.

- Foam: Such as EVA foam, suitable for sports equipment and protective mats.

- Paper: Used for packaging, stationery, and art creations.

- Composite Materials: Like carbon fiber and fiberglass, suitable for high-performance products.

- Ceramics: For customizing mugs, plates, and decorative items.

The versatility of these materials allows UV DTF technology to have broad applications across various industries.

To get started with UV DTF printing, you need three essential components: a UV DTF printer, UV DTF inks, UV DTF film and applicable substrates. These materials work together to create vibrant, durable prints that can be transferred to various products. By investing in high-quality equipment and materials, you can ensure that your UV DTF prints will stand out and last.

Related:

Best Ink for UV DTF Printers: Top Recommendations

Best UV DTF Printer for Small Business

What are the applications of UV DTF

Unveiling the Best Films for UV DTF Printers