Comparison: Sublimation Ovens vs. Heat Presses

In the world of custom printing and product decoration, sublimation has emerged as a popular technique for transferring designs onto various materials. Two primary tools dominate this space: sublimation ovens and heat presses. For businesses and hobbyists looking to invest in sublimation equipment, understanding the differences, advantages, and limitations of each option is crucial for making an informed decision. In this article, we’ll explore both technologies in depth to help you determine which best suits your specific needs.

Understanding Sublimation Technology

What Is Sublimation?

Before diving into the equipment comparison, it’s important to understand the sublimation process itself. Sublimation is a chemical process where a solid transforms directly into a gas without passing through the liquid state. In printing, this involves special sublimation inks that, when heated, convert from solid to gas and bond with polyester or polymer-coated surfaces, creating permanent, vibrant images that become part of the material rather than sitting on top of it.

The Role of Heat in Sublimation

Both sublimation ovens and heat presses serve the same fundamental purpose: providing the necessary heat and pressure to facilitate the sublimation process. However, they accomplish this in different ways, each with distinct advantages for specific applications.

Sublimation Ovens: Features and Benefits

Design and Functionality

Sublimation ovens resemble conventional ovens but are specifically designed to maintain precise temperatures required for the sublimation process. They typically feature:

- Temperature controls with high accuracy

- Digital displays and programmable settings

- Multiple racks for batch processing

- Convection systems for even heat distribution

Advantages of Sublimation Ovens

1. Batch Processing Capabilities

One of the most significant advantages of sublimation ovens is their capacity for batch processing. Unlike heat presses that typically handle one item at a time, ovens can accommodate multiple items simultaneously, making them ideal for high-volume production.

2. Versatility for 3D Objects

Sublimation ovens excel at processing three-dimensional objects such as mugs, water bottles, and irregularly shaped items. The convection heating system ensures that heat reaches all surfaces evenly, resulting in consistent transfers across curved or uneven surfaces.

3. Hands-Free Operation

Once items are placed in the oven and the cycle begins, the process requires no further intervention until completion. This allows operators to focus on other tasks while sublimation occurs.

Sublimation oven transfer design

Limitations of Sublimation Ovens

1. Space Requirements

Sublimation ovens typically require more floor or counter space than heat presses, which may be a consideration for smaller workshops or home-based businesses.

2. Longer Heating Times

Ovens generally take longer to reach operating temperature and may require extended processing times compared to heat presses, potentially impacting production efficiency for certain applications.

3. Less Precise Pressure Control

While heat is distributed evenly in an oven, achieving consistent pressure across the substrate can be challenging, potentially affecting transfer quality for items that require precise pressure.

Heat Presses: Features and Benefits

Design and Functionality

Heat presses are specialized machines that apply both heat and pressure directly to transfer sublimation designs. Common types include:

- Clamshell presses (hinge at the back)

- Swing-away presses (upper platen swings to the side)

- Draw presses (lower platen pulls out like a drawer)

- Specialty presses (designed for specific items like mugs or caps)

Advantages of Heat Presses

1. Precise Pressure Control

Heat presses allow for exact pressure adjustments, ensuring consistent contact between the sublimation paper and substrate. This precision is crucial for flat items like t-shirts, mousepads, and other textiles.

2. Faster Processing Times

Heat presses typically reach operating temperature more quickly than ovens and often require shorter dwell times to complete the sublimation process, increasing production efficiency for single items.

3. Compact Footprint

Many heat press models are designed with space efficiency in mind, making them suitable for smaller workspaces or businesses with limited room for equipment.

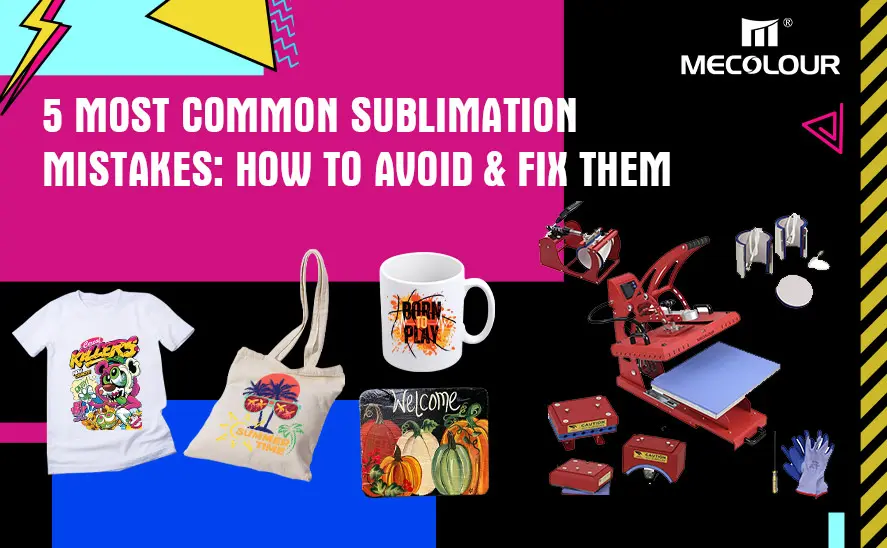

Heat press machine transfer design

Limitations of Heat Presses

1. Single-Item Processing

Standard heat presses can only process one item at a time, which may create production bottlenecks for high-volume operations.

2. Challenges with 3D Objects

While specialty heat presses exist for items like mugs, standard flat heat presses struggle with three-dimensional or irregularly shaped objects, limiting versatility.

3. Operator Attention Required

Heat presses typically require an operator to be present throughout the process to load, unload, and monitor transfers, making them more labor-intensive than ovens for certain applications.

Comparing Cost Considerations

Initial Investment

Heat Presses: Entry-level models start around $200-$300, with professional-grade equipment ranging from $1,000 to $3,000+

Sublimation Ovens: Generally more expensive, with basic models starting around $500 and commercial units ranging from $2,000 to $10,000+

Operating Costs

Both technologies consume electricity, but their efficiency varies:

Heat presses typically use less energy per item but may be less efficient for multiple items

Ovens consume more power overall but can be more cost-effective when processing multiple items simultaneously

Return on Investment

The ROI calculation depends largely on your production volume and the types of products you create:

For low-volume, diverse product lines: Heat presses often provide faster ROI

For high-volume, consistent product types: Sublimation ovens may offer better long-term value

Application-Specific Considerations

Ideal Applications for Sublimation Ovens

- High-volume production environments

- Businesses focusing on 3D products (mugs, water bottles, ornaments)

- Operations where batch processing is essential

- Production requiring minimal operator intervention

Ideal Applications for Heat Presses

- Textile-focused businesses (t-shirts, bags, apparel)

- Low to medium production volumes

- Operations with space constraints

- Businesses requiring quick turnaround on individual items

Making the Right Choice for Your Business

Assessing Your Production Needs

Before investing in either technology, consider:

- Your typical production volume

- The types of products you’ll be creating

- Available workspace

- Budget constraints

- Labor availability

Considering a Hybrid Approach

Many successful sublimation businesses utilize both technologies:

- Heat presses for flat items and quick, one-off orders

- Sublimation ovens for batch processing and 3D items

This hybrid approach maximizes flexibility and production efficiency across different product types.

Both sublimation ovens and heat presses have distinct advantages that make them valuable tools in the sublimation printing process. The best choice depends on your specific business needs, production volume, and the types of products you create.

Many successful businesses find that as they grow, incorporating both technologies into their workflow provides the optimal balance of efficiency, versatility, and production capacity. By carefully assessing your specific requirements and understanding the strengths and limitations of each option, you can make an informed decision that positions your business for success in the competitive world of sublimation printing.

Related:

New Arrival – Sublimation Oven

T-shirt, Mug, and Hat Printing with an 8 in 1 Heat Press Machine

Mastering Heat Press Techniques for Sublimation Tumblers