Die Cutting Machine

| Model |

ME330C |

|---|---|

| Paper feeding width |

340mm |

| Cutting width |

330mm |

| Cutting speed |

10~800m/s |

| Cutting accuracy |

<+0.1mm |

| Cutting pressure |

1-1000g |

| Output software |

Sign Master/CorelDRAW/AI |

| Power supply |

AC90~240V/50HZ~60HZ |

| Gross weight |

31kg |

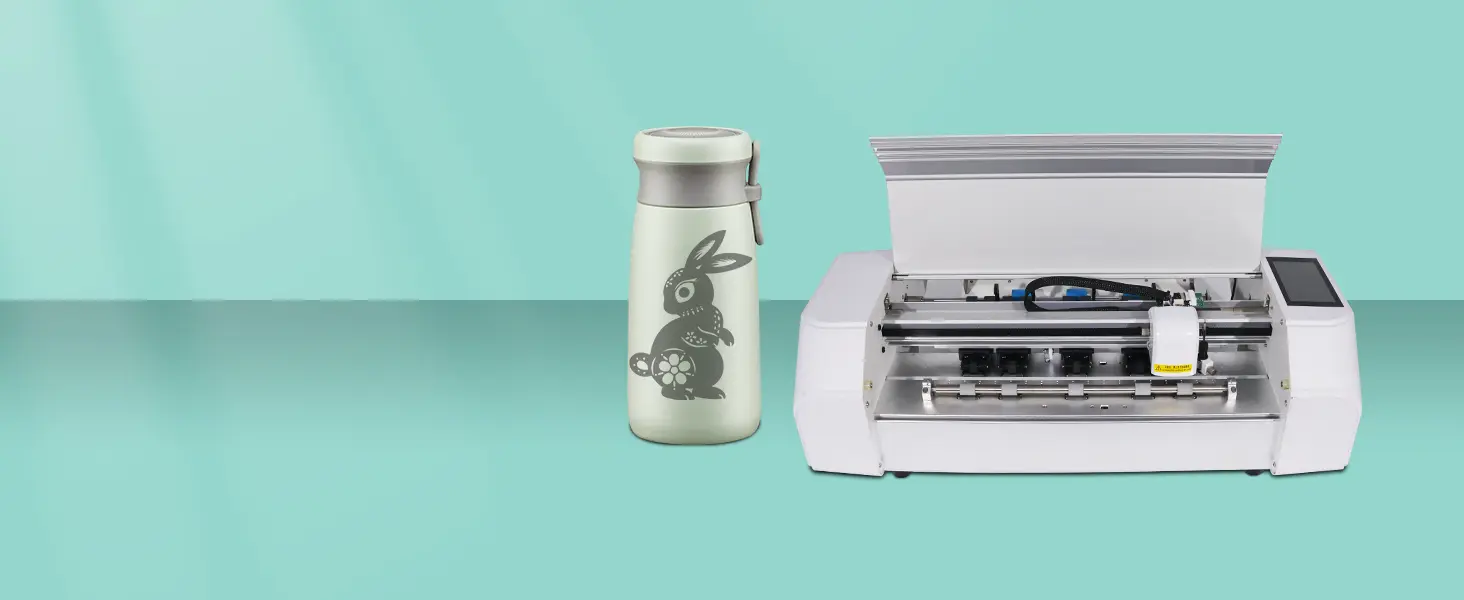

Mecolour Die Cutting Machine

Our die cutting machine is a high-performance, professional-grade tool. This die cut sticker machine is designed for creative enthusiasts and craft makers. Whether you want to create unique greeting cards or personalized gifts, this label die cutter is perfect for you. It’s also great for small batch productions.

Empowering creativity, the arts & crafts cutting machine can die-cut and emboss many materials, from card stock and vellum to leather and mat board.

Discover The Art Of Precision Cutting

Key Features

- Precision Cutting

- Adjustable Pressure

- Increased Efficiency

- Compact Design

- User-Friendly Operation

ME330C Die Cutting Machine Features

Fully Automatic HD Camera Positioning

Supports various self-adhesive materials, automatic positioning & reading; automatic cutting, convenient and fast.

Large-capacity Input Tray

The tray can hold 100 sheets, supports various self-adhesive materials, which is convenient and fast.

Improve Work Efficiency

Automatic paper feeding and fast cutting speed.

High-definition Touchscreen Control

A simple UI interface makes operation easier;

Supports multiple languages.

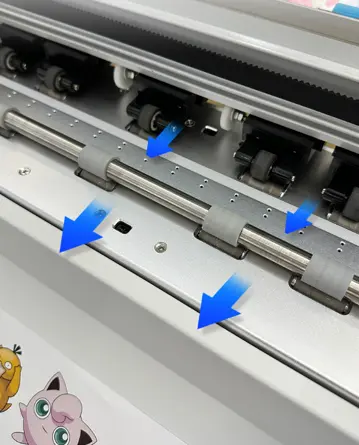

Dual-row Rollers & Reduce Margins

Dual-row roller paper pressing ensures smooth feeding without buckling; Wide cutting range & saving materials

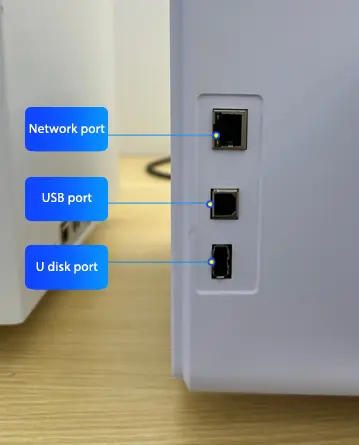

Multiple Transmission Interfaces

Support USB cable/U disk offline operation; Convenient and fast.

Automatic Feeding Die Cutting Sticker Machine

Simple Operation - Specially Designed for You

Install the knife and the knife holder

Adjust the length of the knife appropriately according to the thickness of the product.

Pay attention to the limit of the knife holder when fixing.

Turn on the power

Note that the power switch of the machine is in the off state

Machine model and connection method

Select the machine model:

Choose “MECOLOUR ME330C”

Select the connection method:

Port Type:Windows Port

Port:U_Disk

Contour Cutting

Create Cut-Contour>>Contour Cutting Wizard

Print the file

Print the file according to the required number and save the PLT file in U_Disk.

Setting up the machine and cutting the contour

Put the material into the machine; move the position of the trolley, adjust the speed and pressure according to the material, and test the effect.

Install the knife and the knife holder

Adjust the length of the knife appropriately according to the thickness of the product.

Pay attention to the limit of the knife holder when fixing.

Turn on the power

Note that the power switch of the machine is in the off state

Machine model and connection method

Select the machine model:

Choose “MECOLOUR ME330C”

Select the connection method:

Port Type:Windows Port

Port:U_Disk

Contour Cutting

Create Cut-Contour>>Contour Cutting Wizard

Print the file

Print the file according to the required number and save the PLT file in U_Disk.

Setting up the machine and cutting the contour

Put the material into the machine; move the position of the trolley, adjust the speed and pressure according to the material, and test the effect.

See what customers are making with Mecolour 330C

What control software is used by your machine?

This die cutting machine uses Sign Master/CorelDRAW/AI.

What different languages are supported by the control software?

It supports German, English, Spanish, French, Italian, Portuguese, Russian, Chinese and other languages.

Can the machine be used offline?

Yes, it can be exported via USB flash drive.

What to do if the cutting machine is offset?

When your cutting profile is offset, you need to calibrate the camera.

Why can't the mark point be identified correctly?

If the machine cannot correctly identify the mark point, it may be due to the following reasons:

1. Incorrect Print Size

Reason: If the printed size of the Mark points does not meet expectations, the recognition device may struggle to read them accurately. This could be due to incorrect printer settings, wrong paper size selection, or improper printer calibration.

Solution: Ensure the printer settings are correct, use the appropriate paper size, and perform pre-print calibration to ensure accurate dimensions.

2.Mark Points Not Dark Enough

Reason: Insufficient darkness of the Mark points can lead to recognition difficulties. Poor quality ink or improper printing settings (such as low ink density) can affect the darkness of the Mark points.

Solution: Use high-quality printing ink and paper, and increase the ink density in the print settings to ensure the Mark points are dark enough for easy recognition.

3. Excessive Material Reflection

Reason: If the material surface is too smooth or reflective, light reflections may interfere with the recognition device’s detection, making it difficult to accurately identify the Mark points.

Solution: Choose matte or low-reflection materials, or use anti-reflective coatings during printing to reduce light interference and improve recognition rates.

Specification

|

Product model |

MECOLOUR ME330C |

|---|---|

|

Paper feeding width |

340mm |

|

Cutting width |

330mm |

|

Cutting speed |

10~800m/s |

|

Cutting accuracy |

<+0.1mm |

|

Cutting pressure |

1-1000g |

|

Gross weight |

31kg |

|

Package Size |

L866 x W525 x H315mm |

|

Output software |

Sign Master/CorelDRAW/AI |

|

Power supply |

AC90~240V/50HZ~60HZ |

|

Operation mode |

Splitting, automatic paper feeding |

|

Motherboard |

High-speed subdivision system |

|

Drive |

Stepper motor |

|

Communication port |

Network port/USB/U disk |

|

drawing instructions |

DMPL/HP-GL |

|

Positioning method |

CCD camera positioning |