Blog

T-Shirt Press Safety Measures You Must Follow

Using a t-shirt press can be an efficient and effective way to transfer designs onto garments, but it’s essential to prioritize safety to prevent accidents and injuries. Whether you’re a seasoned professional or a hobbyist, following proper safety measures is crucial to ensure a safe and enjoyable experience. In this article, we’ll discuss the safety measures you must follow when using a t-shirt press.

1. Read the Instruction Manual

Before using t-shirt printing machine, thoroughly read the instruction manual provided by the manufacturer. Familiarize yourself with the equipment, including its features, functions, and safety precautions. Pay close attention to any warnings or guidelines regarding proper usage and maintenance.

2. Wear Protective Gear

When operating a t-shirt press, it’s essential to wear appropriate protective gear to prevent injuries. This includes heat-resistant gloves to protect your hands from burns and safety goggles to shield your eyes from heat and steam. Additionally, wearing closed-toe shoes can help protect your feet from accidental burns or injuries.

gloves

3. Maintain a Clean Workspace

Keep your workspace clean and clutter-free to reduce the risk of accidents and injuries. Remove any obstructions or debris from around the t-shirt press machine to prevent tripping hazards. Ensure adequate ventilation to minimize exposure to heat and fumes generated during the pressing process.

4. Use Heat-Resistant Surfaces

Place the t-shirt press on a heat-resistant surface to prevent damage to countertops or tabletops. Avoid placing the press near flammable materials or surfaces that can be easily damaged by heat. Use a heat-resistant mat or pad underneath the press to provide additional protection and stability.

pad

5. Handle Hot Surfaces with Care

Exercise caution when handling hot surfaces, such as the heating platen of the t-shirt press. Avoid touching the platen directly with your hands, as it can cause burns or injuries. Use heat-resistant gloves or tools to adjust the position of garments and transfer sheets on the platen.

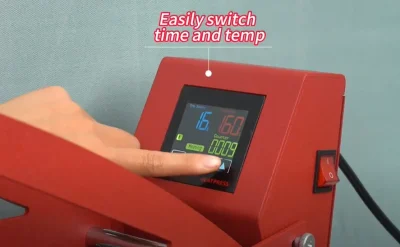

6. Follow Proper Operating Procedures

Follow the manufacturer’s recommended operating procedures when using the t-shirt press. This includes setting the correct temperature, pressure, and pressing time for the type of garment and transfer material being used. Avoid overloading the press or exceeding its maximum capacity to prevent accidents and equipment damage.

7. Monitor the Pressing Process

Stay vigilant and monitor the pressing process closely to ensure everything is proceeding smoothly. Keep an eye on the temperature gauge and timer to prevent overheating or overpressing. If you notice any unusual sounds, smells, or smoke coming from the press, immediately turn it off and investigate the issue.

setting time and tempurature

8. Allow for Cool-Down Time

After completing the pressing process, allow the t-shirt press to cool down before handling or performing maintenance tasks. Never attempt to touch or disassemble the press while it’s still hot, as this can result in burns or injuries. Follow the manufacturer’s recommendations for cool-down times to ensure safe handling.

9.Regularly Maintain and Inspect the Press

Regular maintenance and inspection of your t-shirt press are essential for ensuring its safe and efficient operation. Follow the manufacturer’s recommendations for cleaning, lubrication, and replacement of worn-out parts. Additionally, inspect the press regularly for any signs of damage, such as frayed cords, loose connections, or worn-out heating elements.

Safety should always be a top priority when using a t-shirt press. By following these safety measures, you can minimize the risk of accidents and injuries and enjoy a safe and successful pressing experience. Remember to read the instruction manual, wear protective gear, maintain a clean workspace, use heat-resistant surfaces, handle hot surfaces with care, follow proper operating procedures, monitor the pressing process, and allow for cool-down time.