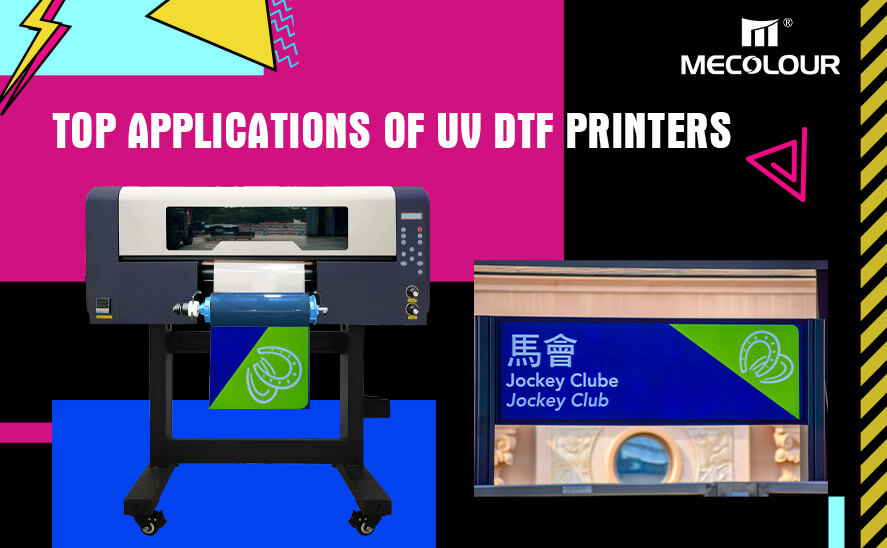

What are the applications of UV DTF?

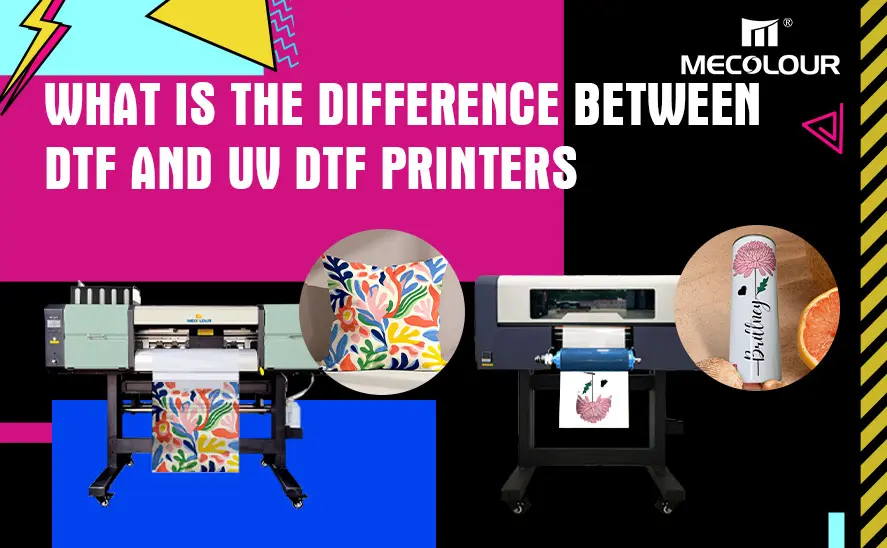

UV Direct-to-Film (DTF) technology has revolutionized the customization industry, offering unparalleled flexibility in decorating various surfaces. The innovative method involves using a UV DTF printer to print vibrant, durable designs onto a transfer film, which are then transferred to different substrates with the help of UV curing. But what exactly can you apply UV DTF to? In this guide, we’ll explore the vast array of materials compatible with UV DTF, highlighting the versatility of UV DTF applications.

UV DTF and Its Applications

UV DTF printing allows businesses and individuals to create vibrant, durable, and detailed designs on a wide range of surfaces. Below, we delve into the key categories of materials compatible with UV DTF.

Popular Surfaces for UV DTF Application

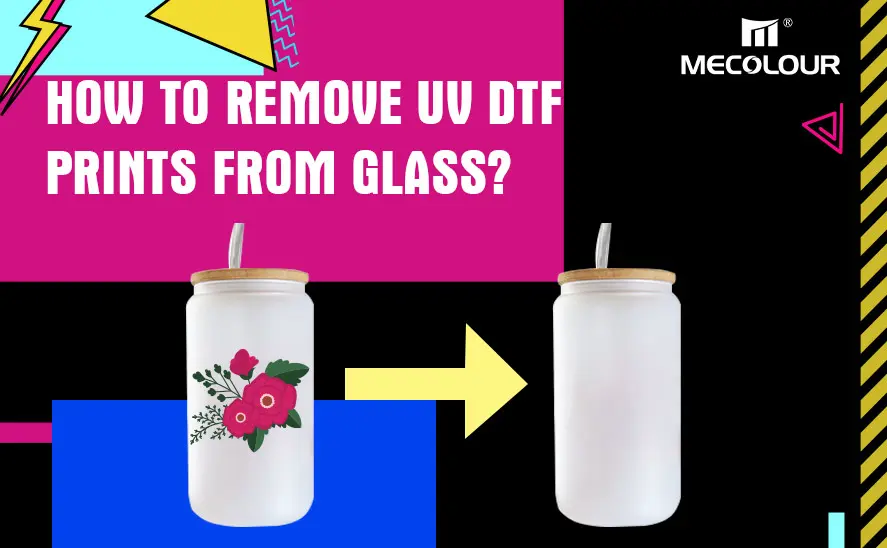

1. Glass

Glass surfaces, whether clear, frosted, or colored, are ideal for UV DTF. The adhesive ensures a smooth and long-lasting bond, making it perfect for:

Custom drinkware like wine glasses and mugs.

Office decor such as nameplates and signage.

Artistic creations like stained glass effects.

2. Metal

Metal surfaces take UV DTF designs exceptionally well due to their rigidity and smoothness. Common applications include:

Custom branding on aluminum or steel water bottles.

Decorative plaques and nameplates.

Industrial labels for machinery.

3. Plastic

UV DTF adheres seamlessly to various types of plastics, opening up applications such as:

Custom phone cases.

Promotional items like pens and USB drives.

Durable labels for containers.

4. Ceramic

Ceramics are another excellent substrate for UV DTF printing. This makes it possible to create:

Personalized tiles for kitchens and bathrooms.

Decorative plates and mugs.

Customized awards and trophies.

5. Wood

Natural and processed wood surfaces can be transformed with UV DTF printing. Popular uses include:

Custom signage for businesses and events.

Home decor items like coasters and plaques.

Artistic wooden crafts.

Popular Surfaces for UV DTF

Specialty Applications for UV DTF

1. Leather and Faux Leather

UV DTF offers an elegant way to customize leather goods, such as:

Personalized wallets and belts.

Custom covers for journals and planners.

Branded promotional products like keychains.

2. Acrylic

Acrylic’s smooth, transparent surface pairs perfectly with UV DTF. It’s used for:

Customized awards and plaques.

Unique home decor items like photo frames.

Display signage with vibrant designs.

3. Fabrics and Textiles

Although UV DTF is not traditionally used for clothing, certain textiles like polyester with a rigid backing can be customized. Think:

Promotional banners.

Tote bags with stiff structures.

Fabric-covered home decor items.

4. Stone and Marble

UV DTF makes it possible to personalize natural stone and marble, ideal for:

Commemorative plaques and awards.

Decorative items for interior design.

Custom coasters and tabletops.

Specialty Applications for UV DTF

Advantages of UV DTF Printing

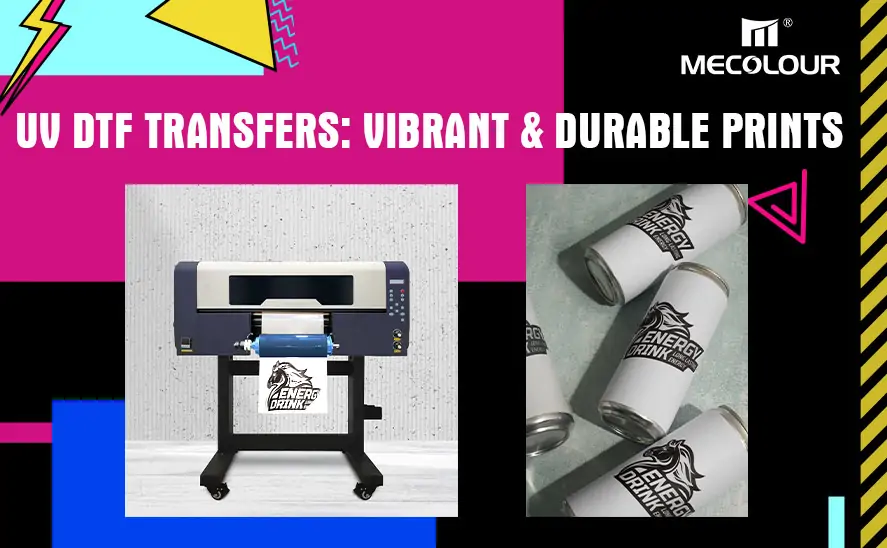

Durability

UV DTF prints are highly resistant to wear, weather, and fading, making them ideal for both indoor and outdoor applications.

Vivid Color Reproduction

The UV-curable inks ensure bright, sharp, and detailed graphics, enhancing the visual appeal of any product.

Versatility

With compatibility across a wide array of materials, UV DTF is a one-stop solution for diverse customization needs.

Eco-Friendly Option

UV curing uses less energy and produces minimal waste compared to traditional printing methods, making it a greener choice.

UV DTF Limitations to Consider

While UV DTF is versatile, it’s important to note its limitations. For instance:

Surfaces must be clean and smooth for optimal adhesion.

Textured or porous materials may require special primers.

Certain untreated fabrics or paper substrates are unsuitable.

Caring for UV DTF Products

To ensure longevity, it’s essential to:

Avoid abrasive cleaning materials on the surface.

Keep UV DTF items away from extreme temperatures.

Gently hand wash items like drinkware or ceramics.

UV DTF technology offers unparalleled versatility, allowing users to personalize a diverse range of surfaces with vivid, durable graphics. From glass and metal to specialty materials like leather and stone, the possibilities are endless. As technology advances, the scope of UV DTF applications continues to expand, making it an essential tool for customization projects.

Related:

UV DTF Transfers: Vibrant & Durable Prints

Unveiling the Best Films for UV DTF Printers

Is UV DTF permanent?