Blog

What is a CNC Wood Router Machine?

A CNC Wood Router Machine is a computer-controlled tool designed to automate the process of cutting, carving, engraving, and shaping wood, plastic, metal, and other materials. Using a CNC (Computer Numerical Control) system, these machines are highly accurate and capable of producing intricate designs with precision, making them indispensable for both professional manufacturers and hobbyists alike.

In this blog, we’ll dive into what a CNC wood router machine is, its applications, and how it can transform your projects–whether you’re working on small-scale crafts or large industrial designs.

What is CNC Technology?

CNC technology refers to the use of computers to control machine tools like routers, lathes, mills, and more. This allows for precise, automated movements that would be difficult or impossible to achieve manually. The machine follows a series of pre-programmed commands in the form of G-code, which controls the tool’s movements along the X, Y, and Z axes.

For wood routers, this means you can achieve intricate cuts, detailed engravings, and smooth finishes with remarkable accuracy.

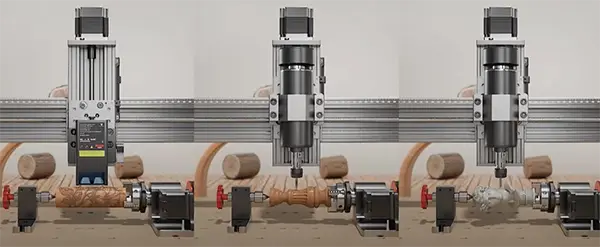

How Does a CNC Wood Router Work?

A CNC wood router operates in a similar way to traditional woodworking routers, but with much more precision. Here’s how it works:

Design:The process starts with designing your project in a CAD (Computer-Aided Design) program. You can create 2D or 3D models depending on the complexity of your project.

Conversion to G-code: The system then converts the design into G-code, a language that instructs the CNC machine on exactly where and how to move, the speed of the router, and the depth of cuts.

Setup: Once you set up the machine with the correct tooling (such as end mills, drills, or engraving bits), you load the material (wood, plastic, or other materials) onto the router bed.

Execution: The CNC router follows the instructions from the G-code, precisely cutting, carving, or engraving the material. The automated movements of the router reduce human error and speed up the process.

Finishing: After the machine has finished, you may need to sand or finish the piece for a smooth surface, depending on the type of project.

CNC Wood Router Work

Applications of CNC Wood Router Machines

The versatility of a CNC wood router machine makes it a go-to tool for a wide variety of applications. Here are some of the most common areas where CNC wood routers are used:

1. Rapid Prototyping

CNC wood routers are ideal for rapid prototyping because they allow designers and engineers to generate models of their projects in a short time. Whether you’re developing a new product, a mechanical part, or a design concept, the ability to quickly iterate and create physical models is essential.

How CNC Routers Help:

- Quick turnaround for creating prototypes.

- High precision for testing design fit and functionality.

- Ability to work with multiple materials, including plastics and composites.

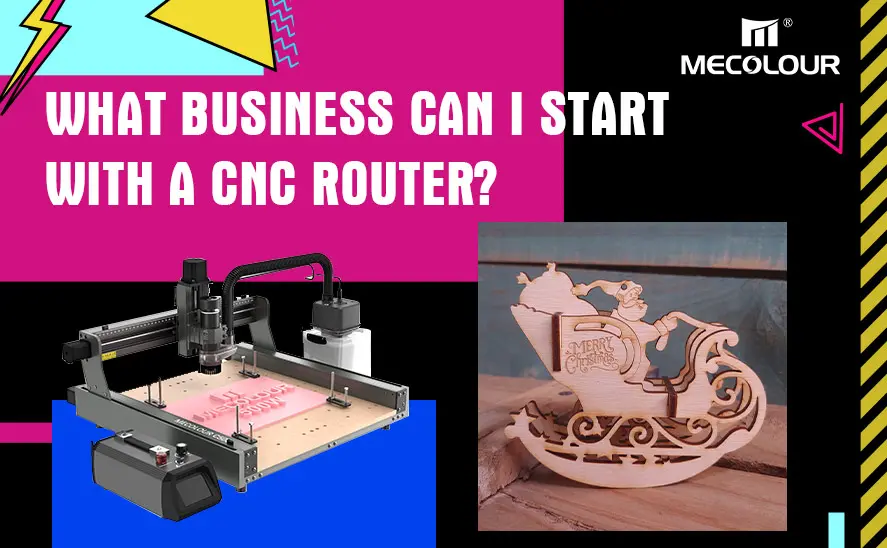

2. Personalized Gifts and Products

With a CNC router, creating customized and personalized items has never been easier. Whether it’s custom engraving on wooden plaques, personalized gifts, or bespoke furniture, these machines can bring your unique ideas to life.

Common Products:

- Engraved gifts like nameplates, keychains, and coasters.

- Custom furniture pieces with intricate designs and engravings.

- Wooden decorations for homes, offices, and events.

Applications of CNC Wood Router

3. Product Prototypes

For small manufacturers or even DIY creators, CNC wood routers are invaluable when it comes to producing product prototypes. These machines quickly transform digital designs into physical products that engineers can test and refine.

Key Advantages:

- Fast iteration of prototypes.

- High-quality, accurate results.

- Ability to work on both large and small-scale prototypes.

4. Design and Engineering Projects

CNC routers excel in producing detailed engineering projects that require both precision and complexity. Whether it’s architectural models, custom jigs, or other technical projects, CNC wood routers are up to the task.

Engineering Applications:

- Precision cuts for technical designs.

- Complex engraving for models and prototypes.

- Producing customized components for larger systems.

5. Small Parts Manufacturing

In industries where small parts are needed, CNC wood routers are perfect for producing small, intricate components. From gears to brackets and decorative pieces, the high level of detail provided by CNC routers is essential in producing these parts efficiently and accurately.

Benefits for Small Parts:

- Fine detail for small-scale production.

- Consistency in creating identical parts for mass production.

- Cost-effective for low-volume production runs.

Why Choose a CNC Wood Router Machine?

There are several reasons why CNC wood router machines are a must-have for a wide range of applications:

Precision: CNC routers deliver unmatched precision, making them perfect for detailed cuts, engravings, and designs.

Efficiency: These machines significantly increase productivity by automating tasks that would otherwise take a long time to complete manually.

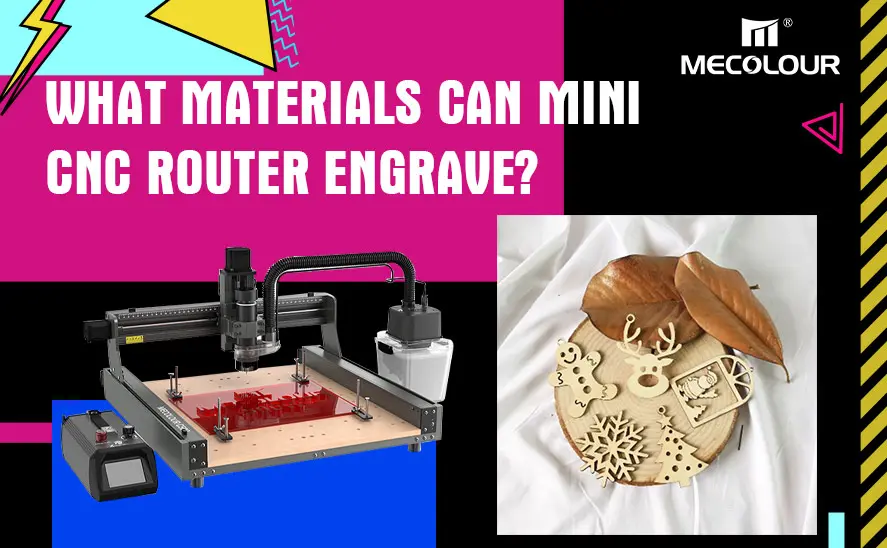

Versatility: CNC routers can handle a variety of materials, including wood, plastic, metal, and even stone, making them highly versatile.

Customization: With a CNC router, you can create customized products or prototypes tailored to your specific needs or design ideas.

Reduced Labor Costs: Because the process is automated, you reduce the need for manual labor, lowering overall production costs.

Whether you’re a hobbyist, craftsperson, or part of a larger manufacturing team, a CNC wood router machine can be an invaluable tool in bringing your creative visions to life. From personalized gifts and product prototypes to small-scale manufacturing and engineering projects, the possibilities are endless.

cnc router crafts

Investing in a CNC wood router can help you speed up production, improve precision, and bring your ideas into the physical world more efficiently than ever before.