Blog

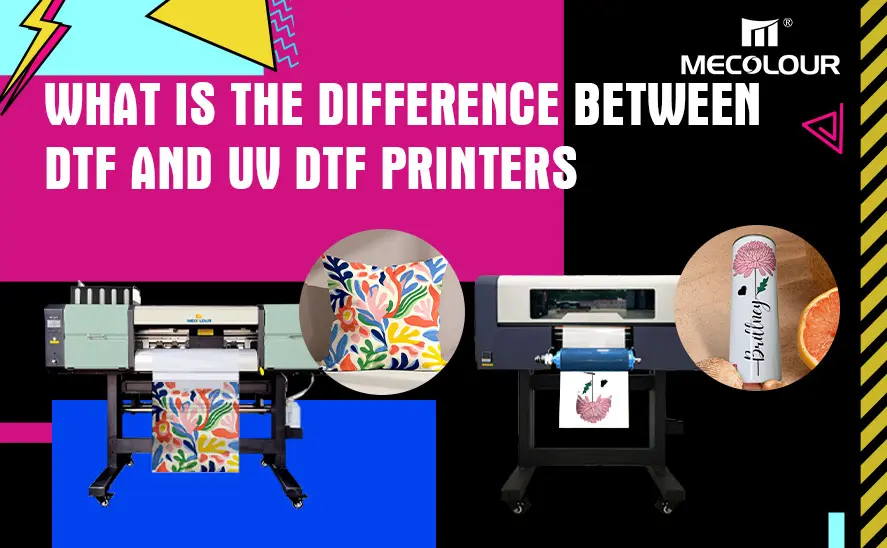

What is the difference between DTF and UV DTF printer?

Direct to Film (DTF) and UV Direct to Film (UV DTF) printers are both cutting-edge technologies used in the printing industry. While they share some similarities, they cater to different applications and offer unique advantages. This article explores the key differences between DTF printer and UV DTF printer to help you understand which one is best suited for your needs.

DTF Printers

Overview

DTF printers are specialized printers designed to transfer designs onto a variety of textiles and fabrics. This process involves printing a design onto a special transfer film, applying adhesive powder, and then using heat to transfer the design onto the fabric.

How DTF Printing Works

Design Creation: Create the design using graphic design software.

Printing: Print the design onto the transfer film using the DTF printer.

Adhesive Application: Apply a powder adhesive to the printed film.

Curing: Cure the adhesive powder by passing the film through a heat press or curing oven.

Transfer: Place the film onto the fabric and use a heat press to transfer the design.

Advantages of DTF Printing

Versatility: DTF printers can print on a wide range of fabrics, including cotton, polyester, and blends.

Durability: The prints are highly durable and can withstand multiple washes without fading or cracking.

Cost-Effective: DTF printing is cost-effective, especially for small to medium-sized production runs.

High-Quality Prints: Produces vibrant and detailed prints with a soft hand feel.

DTF Printing application

UV DTF Printer

Overview

UV DTF printers combine UV printing technology with direct-to-film methods to produce high-quality, durable prints. This technology is primarily used for printing on hard surfaces like glass, metal, wood, and plastic.

How UV DTF Printing Works

Design Creation: Design your artwork using graphic design software.

Printing: Print the design onto a UV DTF film using UV inks.

UV Curing: Immediately cure the UV inks using UV light, which is integrated into the printer.

Adhesive Application: Apply an adhesive layer to the printed film.

Transfer: Use a laminating machine or heat press to transfer the design onto the desired substrate.

Advantages of UV DTF Printing

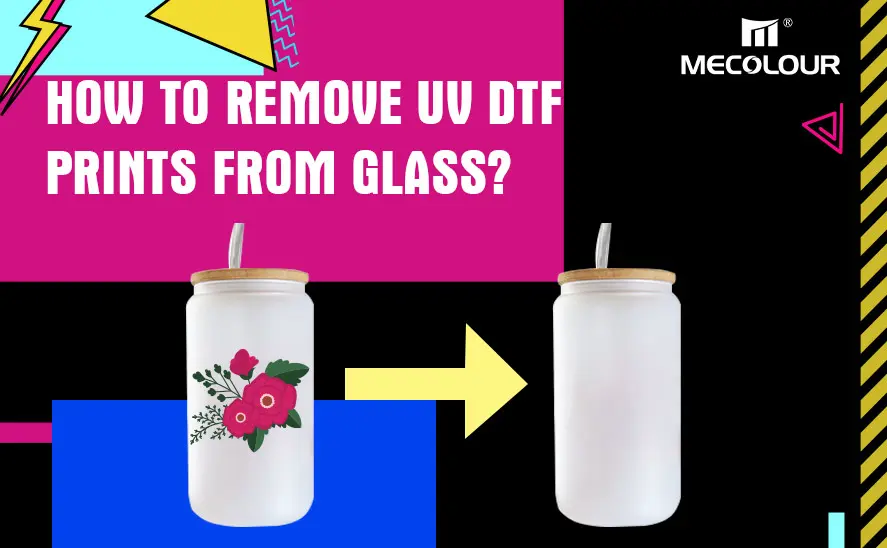

Print on Various Surfaces: UV DTF printer can print on a wide range of non-porous surfaces such as glass, metal, plastic, and ceramics.

Instant Curing: UV inks cure instantly when exposed to UV light, allowing for immediate handling and processing.

High Durability: UV prints are highly resistant to scratches, water, and UV light, making them ideal for outdoor applications.

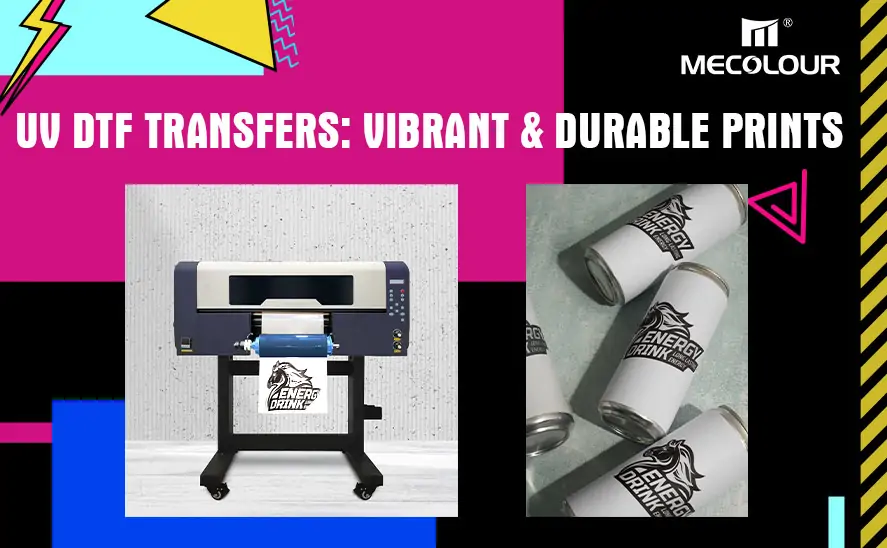

Vibrant Colors: Produces bright, vibrant colors with excellent detail and clarity.

UV DTF Printing application

Key Differences Between DTF printing and UV DTF Printing

Applications

DTF Printers: Best suited for printing on fabrics and textiles, making them ideal for the apparel industry.

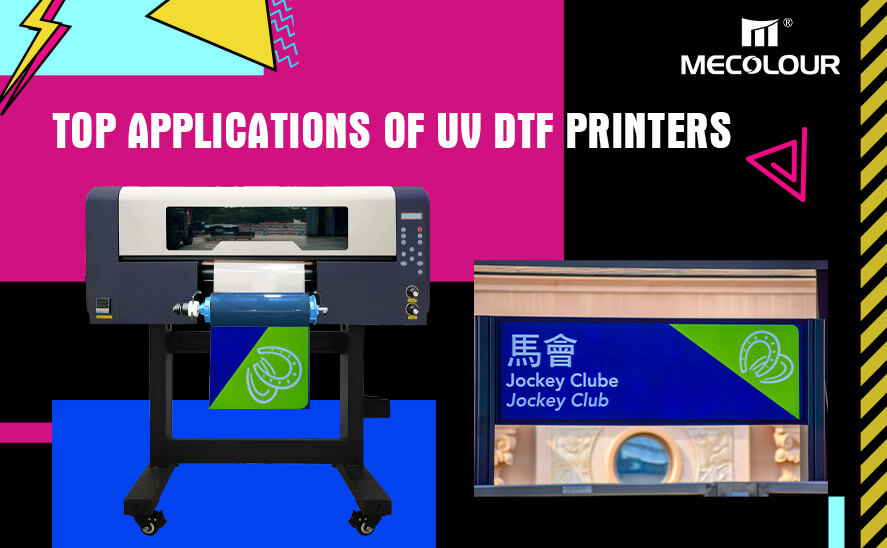

UV DTF Printers: Designed for printing on hard, non-porous surfaces, making them suitable for promotional items, signage, and decor.

Printing Process

DTF Printing: Involves a multi-step process including adhesive powder application and heat transfer.

UV DTF Printing: Uses UV light to instantly cure inks, simplifying the process and reducing production time.

Ink Types

DTF Printers: Use water-based pigment inks that are eco-friendly and safe for fabric use.

UV DTF Printers: Use UV-curable inks that are designed to adhere to hard surfaces and withstand environmental factors.

Durability

DTF Prints: Durable and flexible, ideal for garments that require frequent washing.

UV DTF Prints: Extremely durable, resistant to wear and tear, and perfect for items exposed to the elements.

Versatility

DTF Printers: Versatile in terms of fabric compatibility.

UV DTF Printers: Versatile in terms of surface compatibility, able to print on almost any non-porous material.

Both DTF printers and UV DTF printers offer unique benefits and are suited for different applications. DTF printers excel in fabric printing, offering vibrant and durable designs for apparel. UV DTF printers, on the other hand, are ideal for hard surfaces, providing high-quality, resilient prints for a variety of items. Understanding these differences will help you choose the right printer for your specific needs and ensure the best results for your printing projects.

Related:

Top Applications of UV DTF Printers

UV DTF Transfers: Vibrant & Durable Prints