Blog

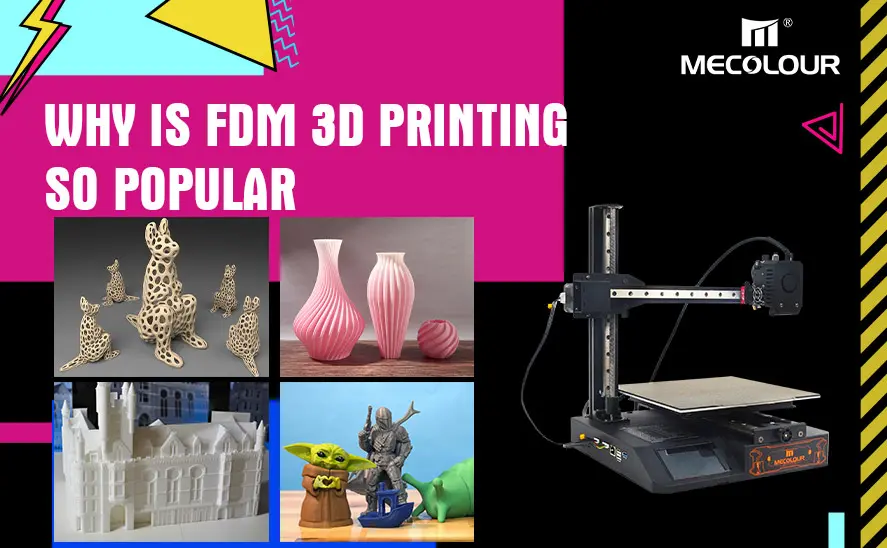

Why is FDM 3D printing so popular?

If you’ve been anywhere near the world of technology lately, you’ve probably heard the buzz about FDM 3D printing. Whether you’re a tech enthusiast, a DIY hobbyist, or just someone curious about the latest trends, you might be asking, “Why is FDM 3D printing so popular?” we’re about to dive into the fascinating reasons behind its soaring popularity.

What is FDM 3D Printing?

Before we delve into why FDM 3D printing is such a hit, let’s get on the same page about what it actually is. FDM 3D printing is a type of additive manufacturing technology. It works by melting plastic filament and extruding it layer by layer to build up a three-dimensional object. It’s a bit like squirting out frosting on a cake, but instead of a sugary treat, you end up with a tangible object!

The Basics of FDM Technology

Material Melting: FDM printers heat up a plastic filament until it melts.

Layer-by-Layer Construction: The melted plastic is deposited in layers, gradually forming the object.

Cooling and Solidifying: Each layer cools and solidifies before the next one is applied.

How To Use Mecolour FDM 3D Printer?

Why Is FDM 3D Printing So Popular?

Here are some compelling reasons that might just blow your mind:

1. Cost-Effectiveness

Let’s face it: high costs can be a deal-breaker. FDM 3D printing shines in this department. It’s one of the most budget-friendly 3D printing technologies out there. Here’s why:

Affordable Materials: Filaments like PLA and ABS are inexpensive and widely available.

Lower Initial Investment: Entry-level FDM printers are reasonably priced, making them accessible for hobbyists and small businesses.

2. Ease of Use

If you’re new to 3D printing, you’ll love how easy FDM printers are to use. They’re designed with user-friendliness in mind. Consider these features:

Beginner-Friendly: Many FDM printers come with simple controls and pre-configured settings.

Straightforward Maintenance: Routine upkeep is usually easy, with many parts being replaceable or upgradable.

3. Versatility

The versatility of FDM printing is nothing short of impressive. It can handle a wide range of applications, from prototyping to end-use parts. Here’s a snapshot:

Prototyping: Quickly create prototypes for design testing.

Custom Parts: Manufacture custom parts or tools tailored to your needs.

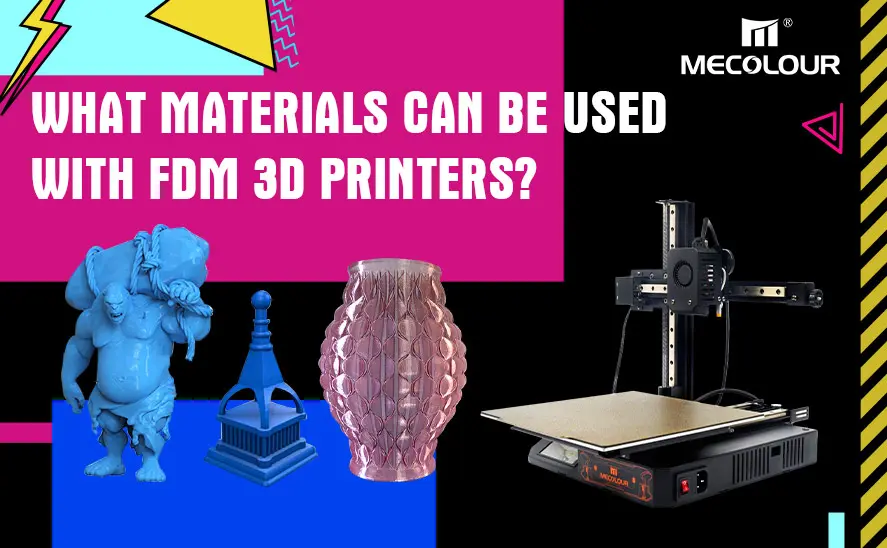

4. Wide Range of Materials

FDM 3D printing isn’t just about one type of plastic. It supports various materials, each with its own unique properties:

PLA (Polylactic Acid): Biodegradable and user-friendly.

ABS (Acrylonitrile Butadiene Styrene): Durable and heat-resistant.

PETG (Polyethylene Terephthalate Glycol): Strong and flexible.

FDM 3D prints

5. Community and Support

Another factor in FDM’s popularity is the robust community that supports it. From forums to social media groups, there’s a wealth of information and resources available. Here’s what you can find:

DIY Tips: A treasure trove of DIY hacks and upgrades.

Troubleshooting: Solutions to common issues and challenges.

6. Rapid Prototyping and Production

Time is often of the essence, and FDM printing delivers on this front. It’s capable of producing prototypes and final products quickly. The key benefits include:

Fast Turnaround: Create prototypes in a matter of hours.

Efficient Production: Small-batch production runs can be completed quickly.

Pros and Cons

Every technology has its ups and downs. Here’s a quick rundown of the pros and cons of FDM 3D printing:

Pros

Affordability: Budget-friendly for both equipment and materials.

Ease of Use: Ideal for beginners and professionals alike.

Material Variety: Broad range of materials to choose from.

Cons

Resolution Limitations: Not always the best choice for highly detailed prints.

Post-Processing: Often requires additional finishing work.

The Future of FDM 3D Printing

So, what’s next for FDM 3D printing? As technology continues to advance, we can expect to see even more exciting developments:

Improved Materials: New filaments with enhanced properties.

Enhanced Speed: Faster print times and higher efficiency.

Innovative Applications: From medical implants to complex engineering solutions.

In a nutshell, FDM 3D printing’s popularity can be attributed to its cost-effectiveness, ease of use, versatility, and the vibrant community that supports it. Whether you’re a hobbyist looking to tinker with new designs or a professional seeking to streamline production, FDM technology has something to offer.

Related:

Exploring FDM 3D Printer Technology

Advantages of FDM 3D Printing